For Schaller & Engine Protection Partner, “safety first” is not just an empty phrase or marketing slogan, it has been part and parcel of our corporate culture and practiced every day for more than 60 years. The VN301plus is based on 50 years experience in oil mist detection. In order to respond to today’s market demands, we at Schaller & Engine Protection Partner have to put considerable thought into how we could make our product even safer and simpler.

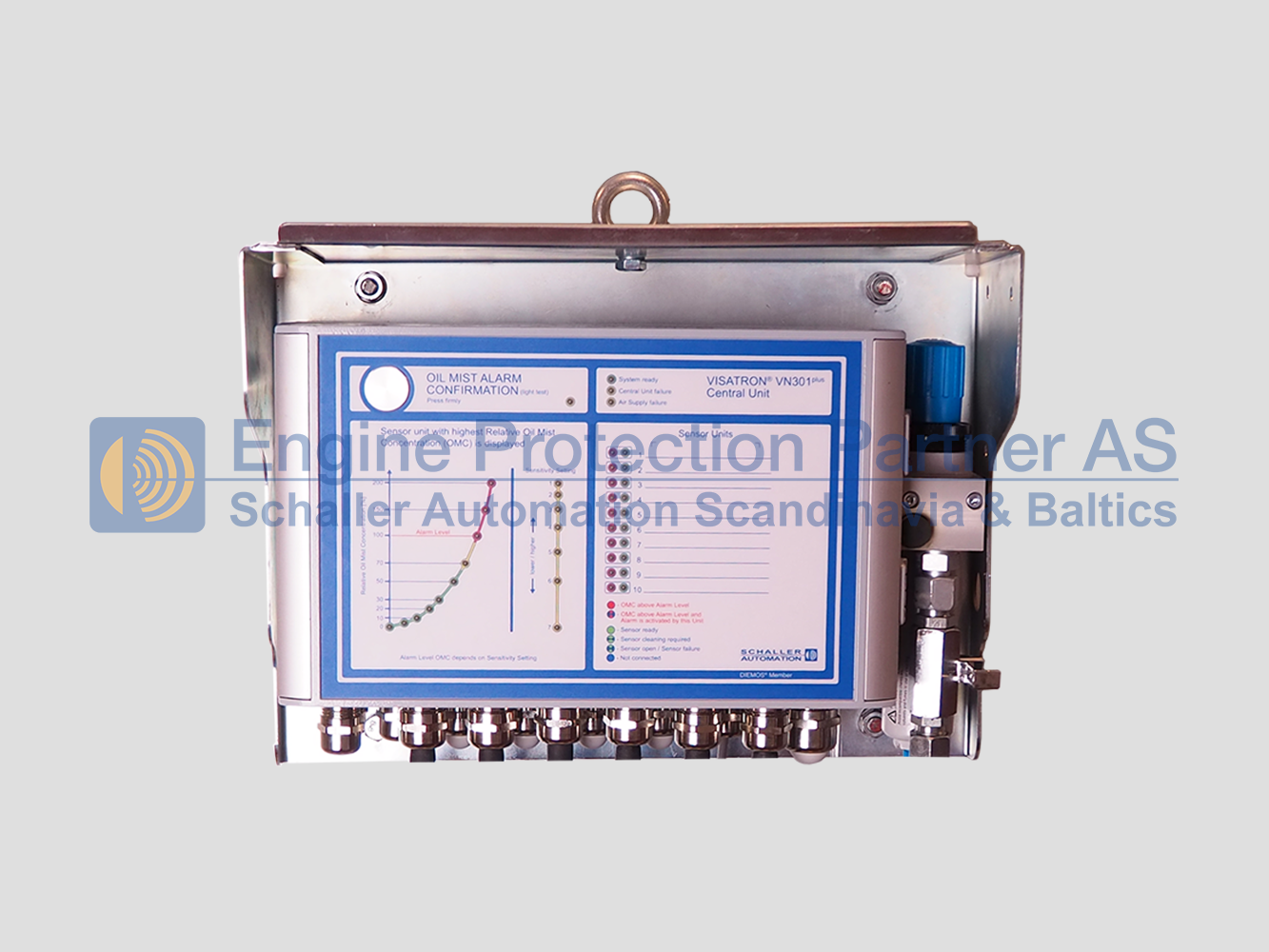

Visatron VN301plus Central unit

The central unit of the VN301plus system has the following functions:

- Disturbing power supply to the sensors

- Providing the operator with necessary information on system status

- Programming and adjustment

The central unit is designs to withstand extreme conditions such as vibrations or high temperature at the engine. All important information is available at a glance. Up to 10 sensor can be connected to the central unit, and up to 20 as master slave version. Our new software makes it possible to calibrate the sensors so they are always perfectly adjusted to the engine operating conditions. Our tried and tested “floating zero algorithm” adapts to the opacity in the crankcase arising from the operation conditions and therefore prevents false alarms. The Remote Indicator II can be connected as an option. The central unit can communicate with modern control systems via ModBus or CANbus. All data in the system is stored in the central unit for analysis.

VN301plus Sensor

The sensor consist of 3 parts:

- Engine wall screw fitting

- Sensor

- Hybrid cable

Flexibility, simplicity and reliability – this is how we control your operating cost more effectively! The engine wall screw fitting allows the sensor to be mounted on the engine and also the intake and return of the crankcase atmosphere. The engine wall screw fitting with is flexible intake funnel is mounted from the outside. Its form prevents splash oil from being drawn in and a false alarm being triggered. We can offer you s suitable engine wall screw fitting to match the engine wall thickness. Schaller has developed a sensor based on the Venturi principle that reduces spare parts and maintenance. It has been redesigned in order to also to achieve a significant reduction in air consumption. Keeping you operating cost under control.

The sensor is connected to the central unit using our hybrid cable. The cable supplies compressed air and power to the sensor and facilitates exchange of data with the central unit.

Visatron VN301plus Cable

Our hybrid cable solution offers flexible installation options and, as always , offers the benefits of our technology which is based on the Venturi principle. And what’s more, there are no wear parts or time- consuming repairs. We use fresh air to keep our sensors completely clear of dirt. This reduces maintenance overheads significantly and rules out false alarms. The no-frills display of our central unit means you quickly gain an overview of the system status. Our products are geared towards Industry 4.0 due to our CAN and Modbus interface options.