Maintenance Plan – VN/87 EMC

The recommended maintenance schedule must be followed as described below to ensure highest safety standard for your engine operation. The maintenance schedule is to be viewed as precautionary measures in relation to technical problems.

It is recommended to use authorized service personnel every 4 years to inspect the entire oil mist detector system to ensure proper functionality of the complete installation.

NOTE: All maintenance steps should be performed while engine is stopped!

1

|

| Every month or 650 hrs. -whatever comes first!

151800 – U- tube gauge or 100138 – Digital u- tube man. |

2 |

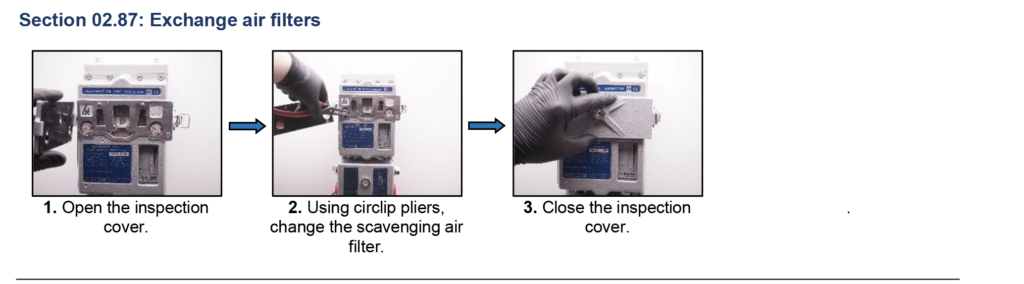

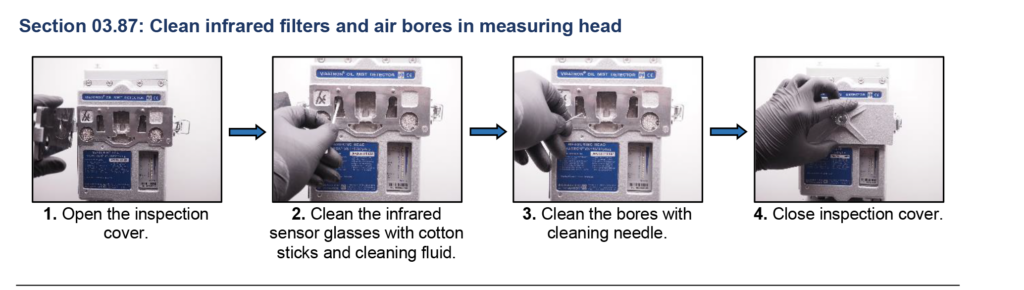

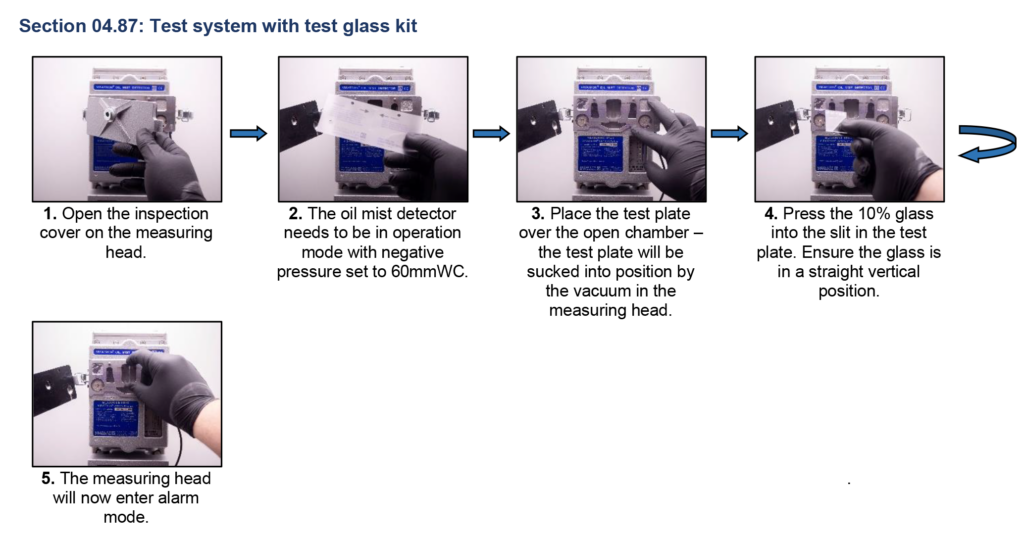

| Every 3 months or 2000 hrs. – whatever comes first!

151481 – Filter kit VN/87 151482 – Cleaning kit 11072- Test glass kit |

3

|

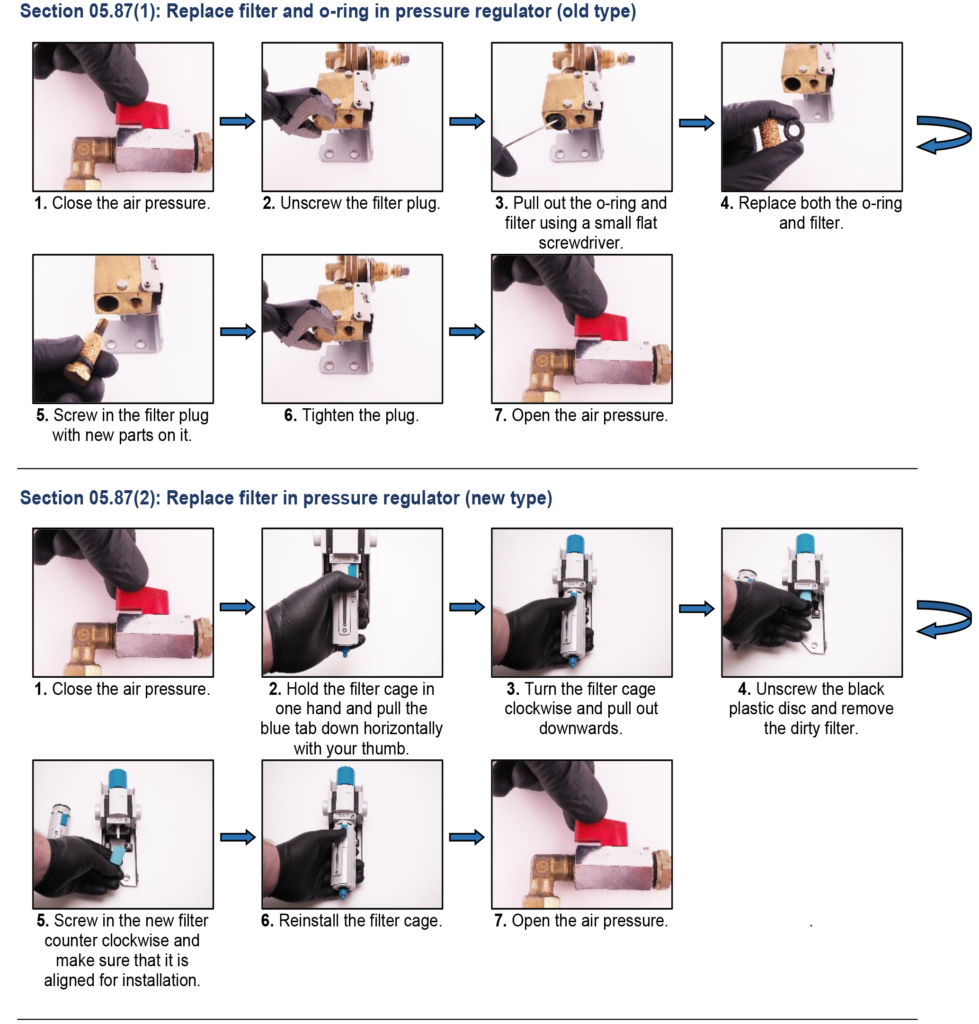

| Every 6 months or 4000 hrs. – whatever comes first!

273119- Filter cartridge |

4 |

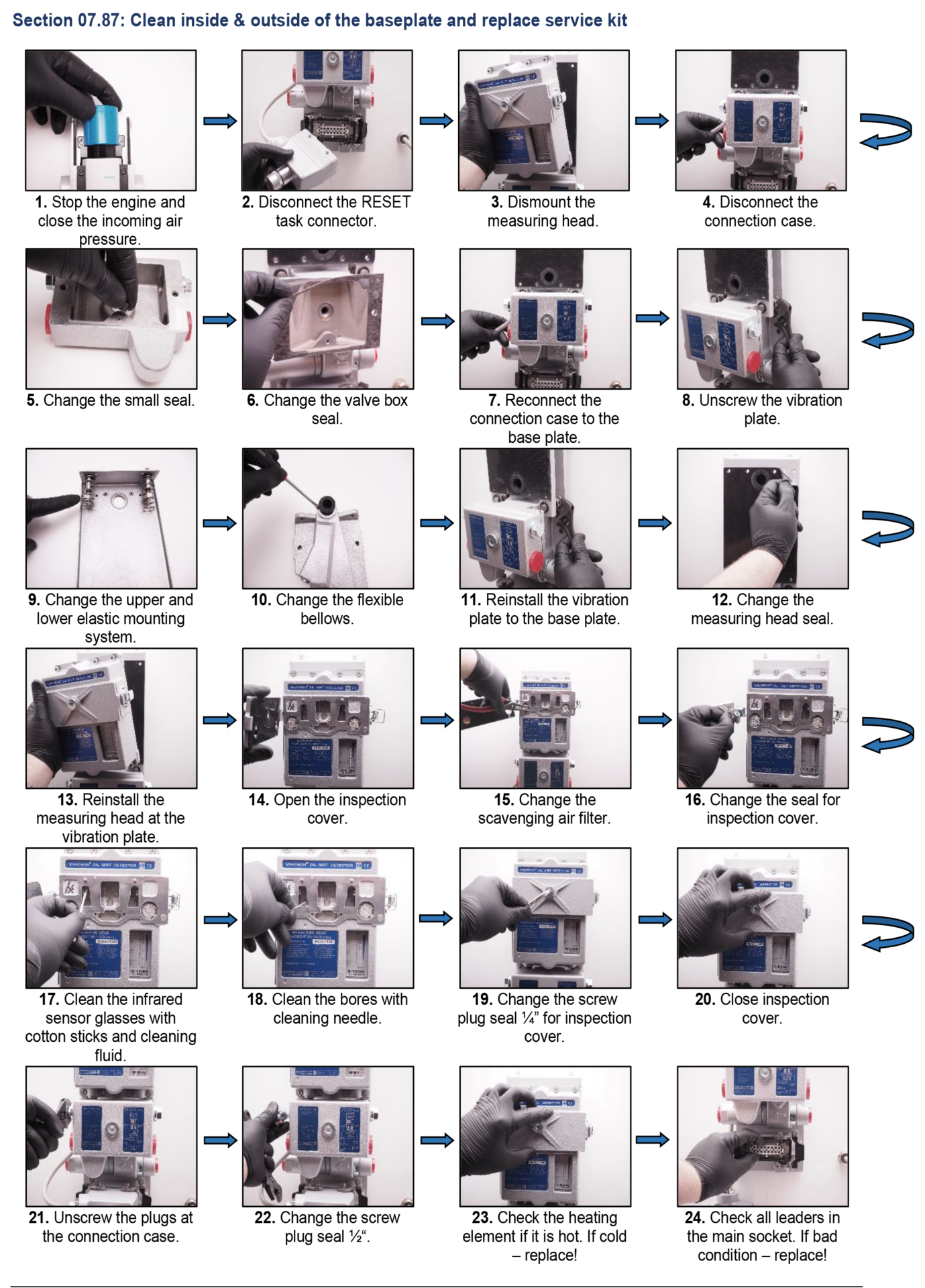

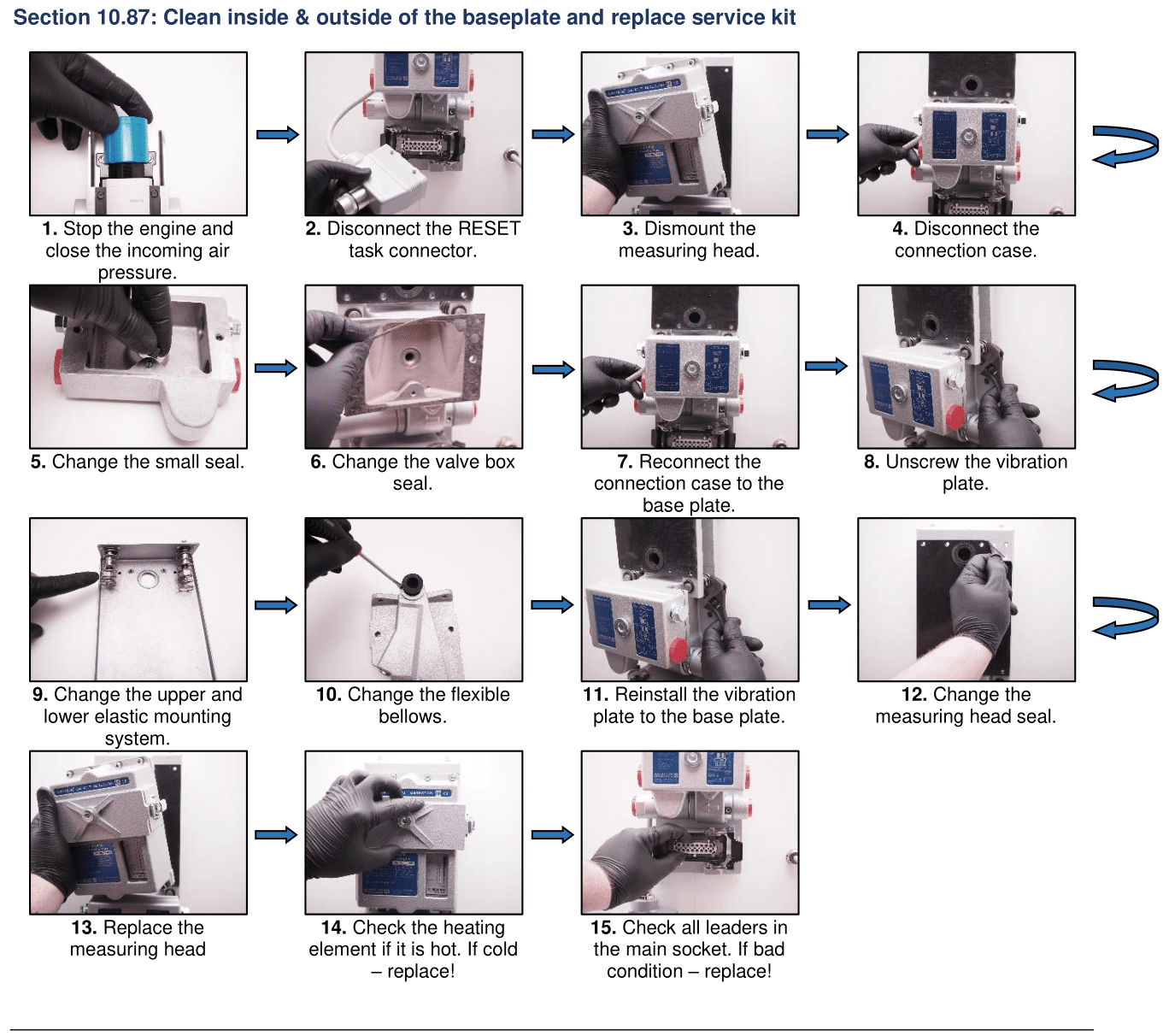

| Every 12 months or 8000 hrs. -whatever comes first!

Service kits: VN 115/87 – P/n.: 100150-151483 VN 116/87 – P/n.: 100151-151484 VN 215/87 – P/n.: 100152-151485 |

5 |

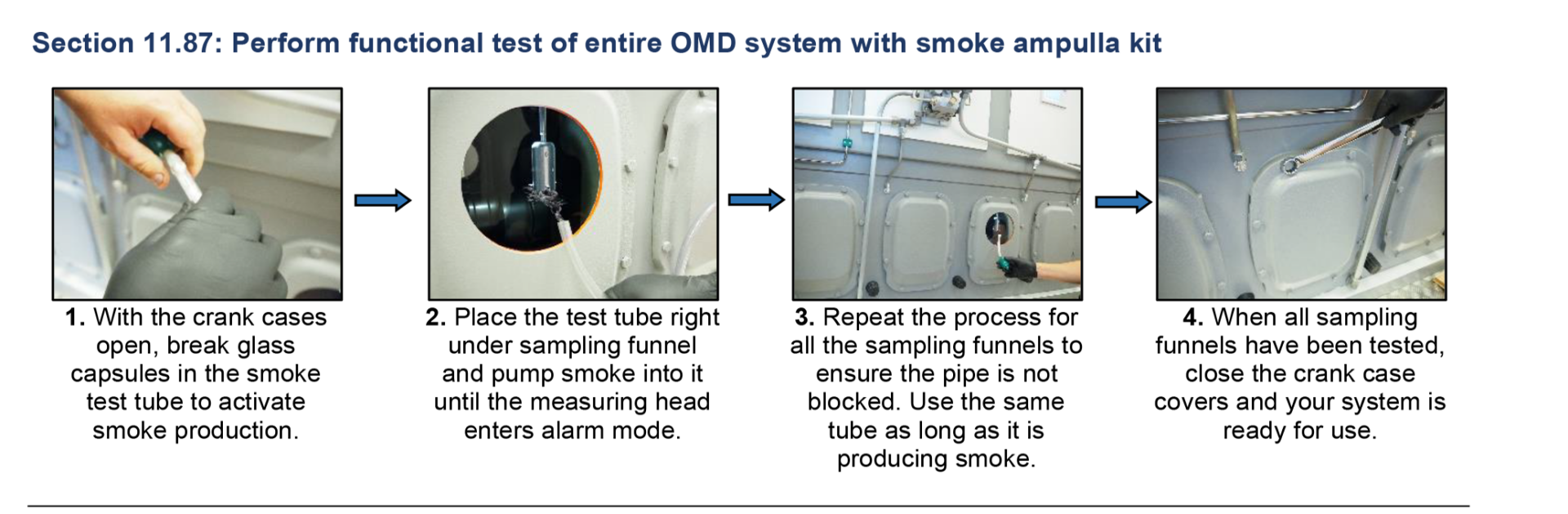

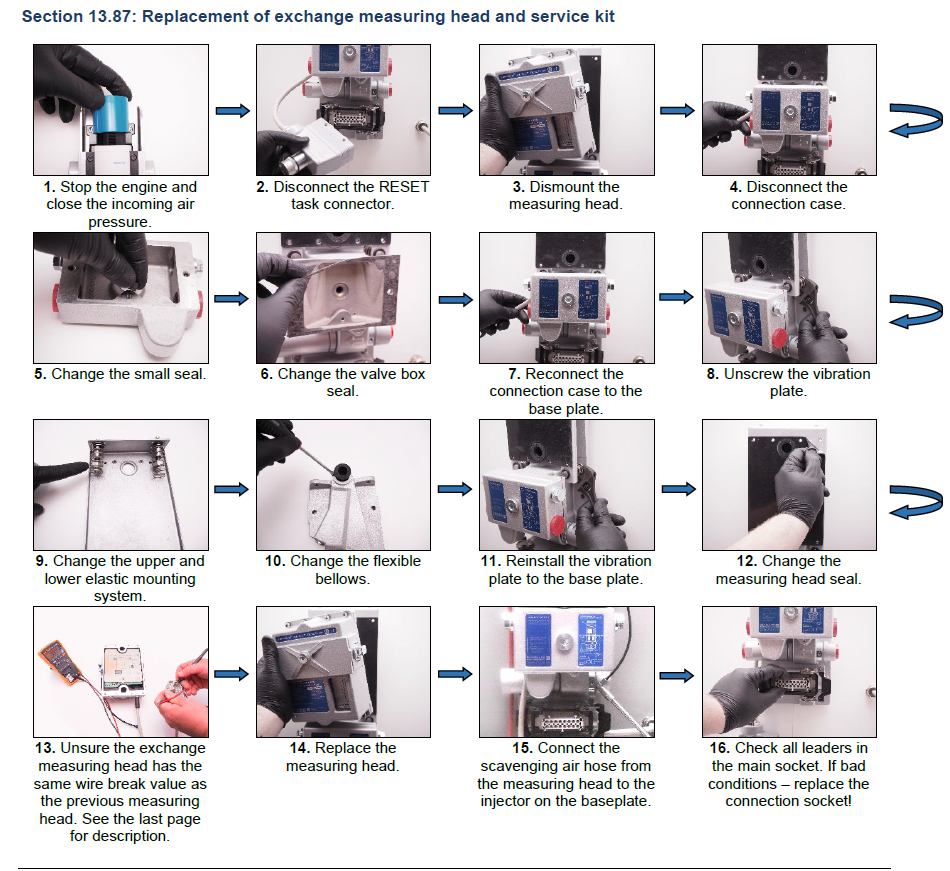

| Every 48 months or 32 000 hrs. –whatever comes first!

Main service kits: VN 115/87 – P/n.: 100150-151483 VN 116/87 – P/n.: 100151-151484 VN 215/87 – P/n.: 100152-151485 151482 – Cleaning kit 151780 – Smoke test kit 150740 – Smoke test generator Exchange Pool (EXP): Please contact us at epp@epp.no to find your specific exchange unit! |

Note: When Exchange Pool (EXP) solution is used instead of Authorized Service Personnel (ASP) on 48 months or 32 000 hrs. maintenance, Engine Protection Partner AS and Schaller Automation are not legally responsible of any failures, damages or other consequences caused by the oil mist detector pipe system described in chapter 12.87!

ASP – Authorized Service Personnel is authorized by Schaller Automation only!