Maintenance

Authorized Repair Service Center

The repair and service department is authorized by Schaller Automation GmbH & Co, and it is known for high quality in all stages with the latest technology in use. Our workshop has become known for quick repairs and first class service. All completed repairs goes through extensive tests and are delivered with full documentation. The repair department is certified according to DIN EN ISO 9001:2015.

The repair department is separate into two departments: electronic repairs and mechanical repairs. Engine Protection Partner AS ensures always highly skilled personnel specialized for the different repair processes. In the electronic repair department, you will find the latest repair technology based on the POLAR robot fault locators.

The repair department is flexible, so if you require urgent service/repair of your Visatron oil mist detector – please contact us, we always find good solutions!

Authorized Service On-Site

We have our own highly skilled service crew for service on vessels and power plant locations. We are making sure that the complete system works according to the specified instructions of the system. This means that we are checking and testing not only the oil mist detector – but the complete oil mist detector installation with sampling funnels, tubing system, pressure reducer etc.

Engine Protection Partner’s service crew operates in Norway, Sweden, Denmark, Faroe Islands, Finland, Iceland, Estonia, Latvia and Lithuania. In countries outside this area, we use our Schaller Automation network. Beside of our main region, we are presented with service crew in Asia, Europe and USA.

Maintenance schedules

It is always a good solution to do maintenance on your Visatron oil mist detector system with a view to be precautionary in relation to technical problems. This eliminates the risk of downtime of the oil mist detector and the engine.

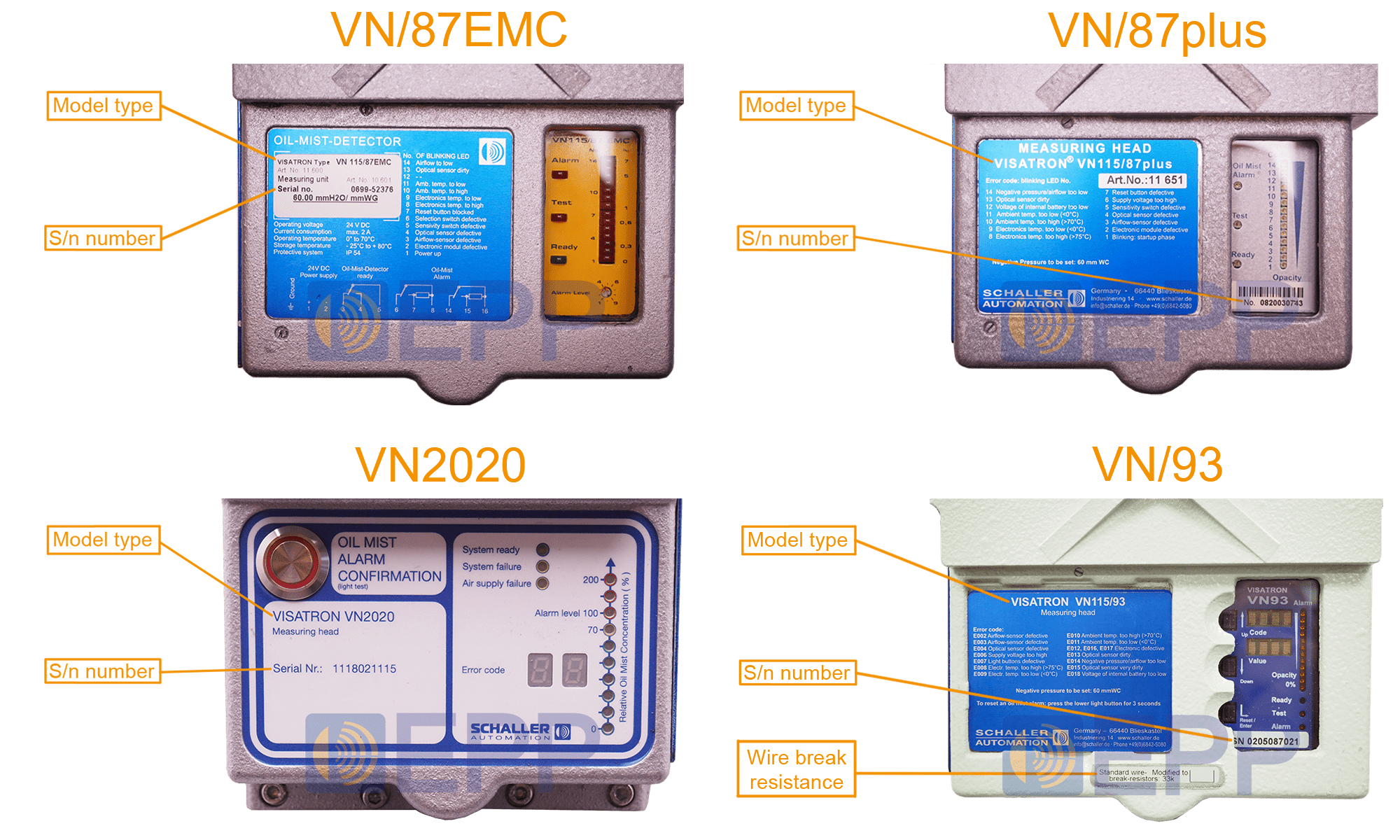

Below you will find how to test your oil mist detector system and the maintenance schedules for the different oil mist detector systems.

According to makers manual for VN/87plus, VN/93 and VN2020, to fulfill class requirement, authorized service personnel has to be used every 2 years for inspection of entire oil mist detector installation.

Other important information regarding maintenance of your system

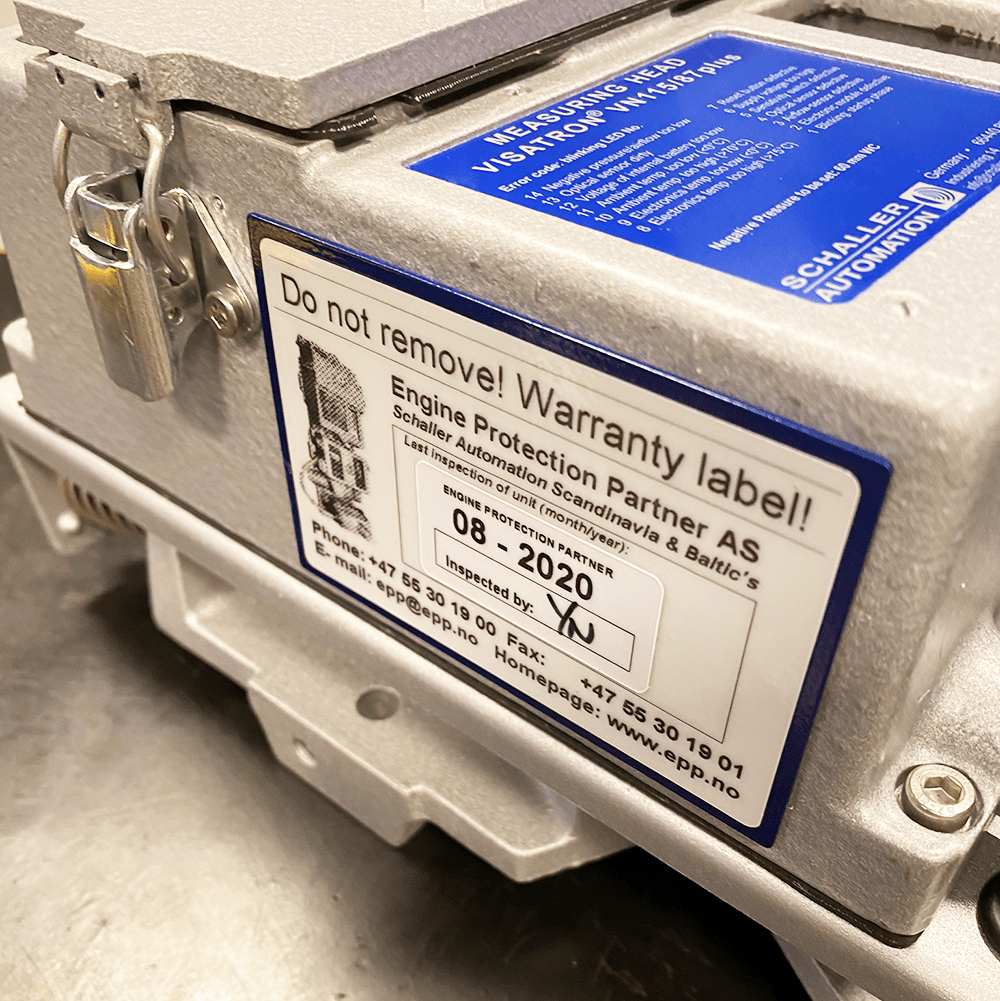

The warranty labels are placed on the right side on VN2020 measuring heads and on the left side on any other measuring head – do not remove the label under any circumstance! This label indicates the last time the system have been overhauled/calibrated by authorized service personell. The warranty label is marked with the month and the year it was overhauled and signed by the person who verified the finished product. It also indicates the validity period of warranty.

The warranty labels are placed on the right side on VN2020 measuring heads and on the left side on any other measuring head – do not remove the label under any circumstance! This label indicates the last time the system have been overhauled/calibrated by authorized service personell. The warranty label is marked with the month and the year it was overhauled and signed by the person who verified the finished product. It also indicates the validity period of warranty.