Maintenance Plan – VN2020

It’s a good solution to maintenance your Visatron VN2020 Oil Mist Detector system with a view to be

precautionary in relation to technical problems. This eliminates the risk of downtime of the oil mist detector

and the engine. The following table lists the maintenance cycles for the VN2020 oil mist detector.

By conducting regular maintenance, the product will have a long service life. If the maintenance intervals are not observed, the oil mist detector may fail prematurely. It is essential that you follow the given sequence for the work. NOTE: All maintenance steps should be performed while engine is stopped!

According to maker’s operation manual, an inspection of the entire OMD installation on board has to be executed by authorized service staff every 2-years or 16 000 operating hours – whatever comes first!

| What to do: | Interval: | Part kit: |

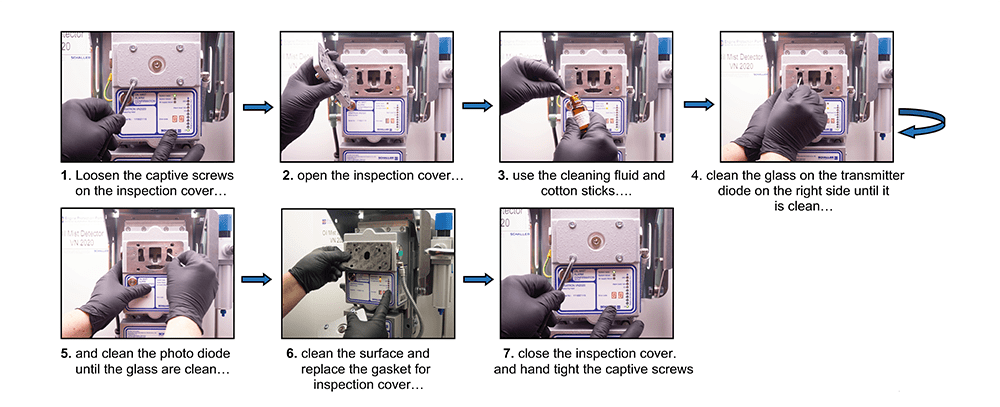

Procedure 1 |

| Every 6 months or 4 000 operating hours. (whatever comes first) | Maintenance kit for VN2020 – Part no.: 155006 Cleaning kit – Part no.: 151482 Smoke test kit – Part no.: 151780 |

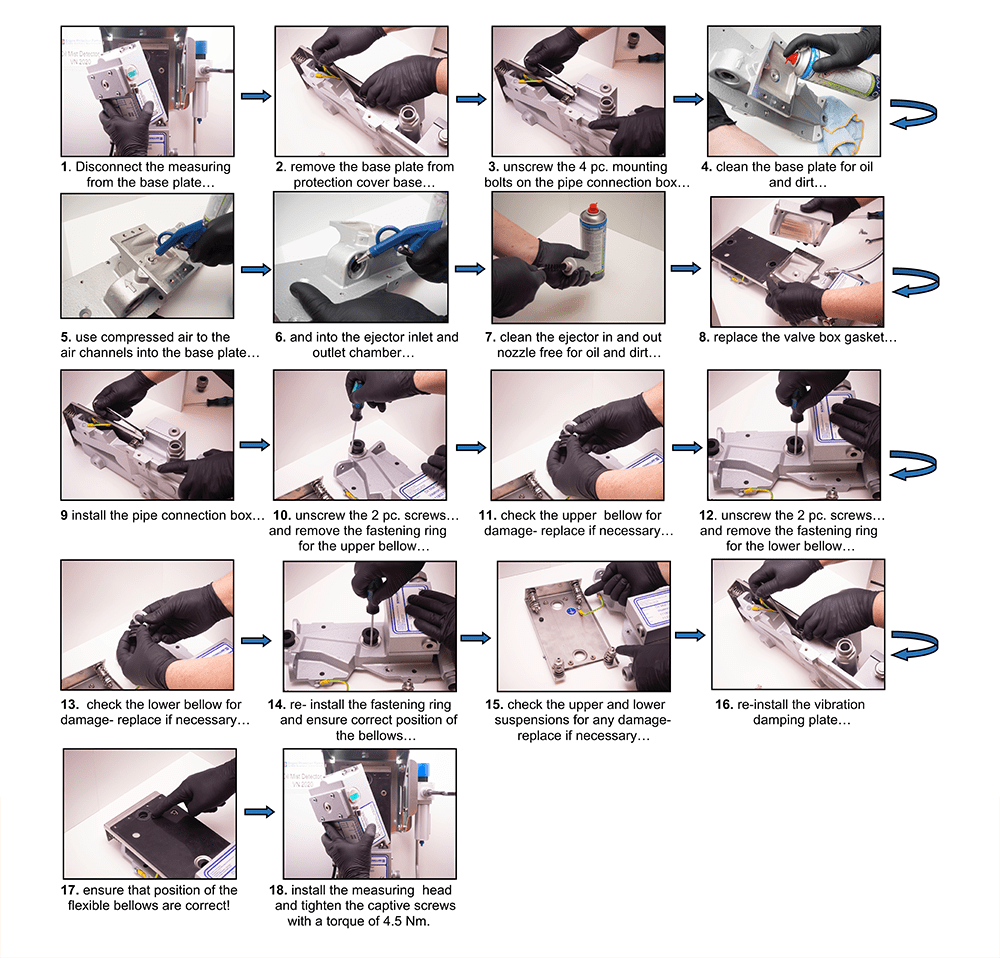

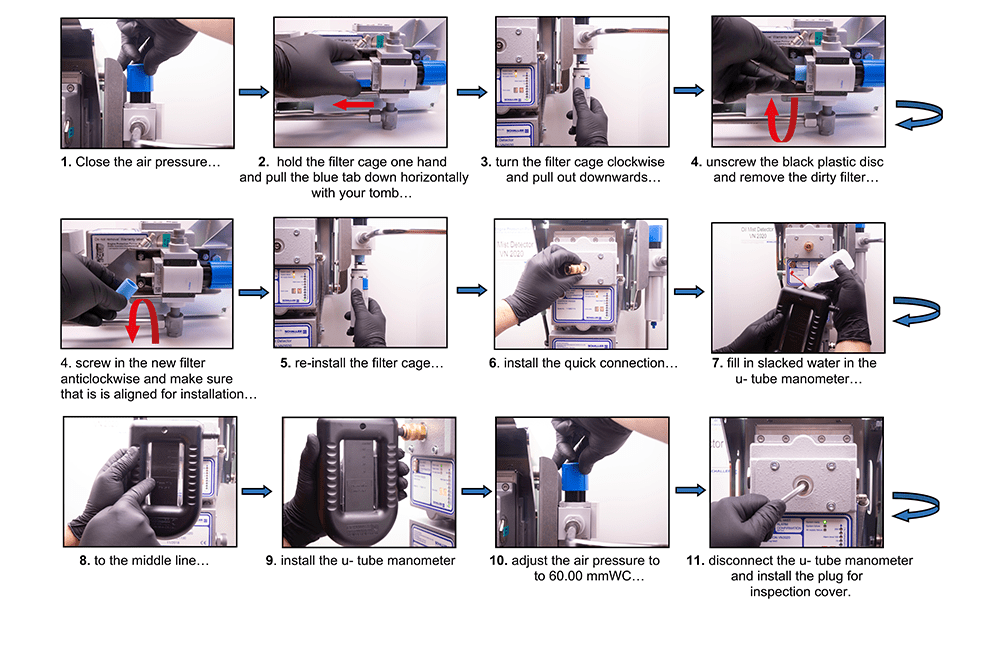

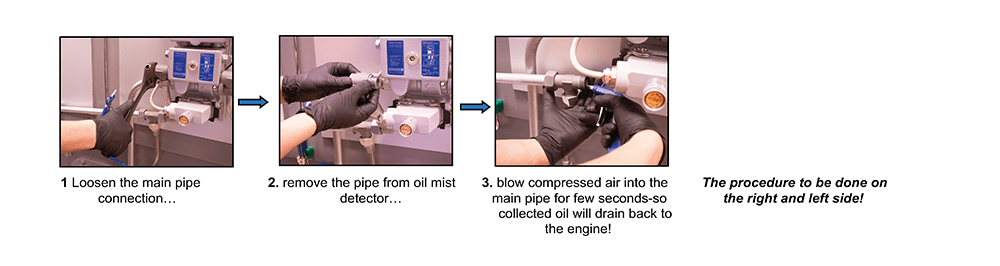

Procedure 2 |

| Every 12 months or 8 000 operating hours. (whatever comes first) | Service kit for VN2020 – Part no.: 155004 Cleaning kit – Part no.: 151482 Smoke test kit – Part no.: 151780 |

Procedure 3 | Main two-year service (2 years) by authorized and certified Schaller personnel only!

Please contact us for authorized personnel at: epp@epp.no | Every 24 months or 16 000 operating hours. (whatever comes first) | Service kit for VN2020 – Part no.: 155004 Cleaning kit – Part no.: 151482 Smoke test kit – Part no.: 151780 |

This system requires service by authorized Engine Protection Partner/Schaller Automation personnel every 2 years to ensure that the complete oil mist detector installation meet the makers requirements. According to maker’s operation manual, an inspection of the entire OMD installation on board has to be executed by authorized service staff every 2-years or 16 000 operating hours – whatever comes first!