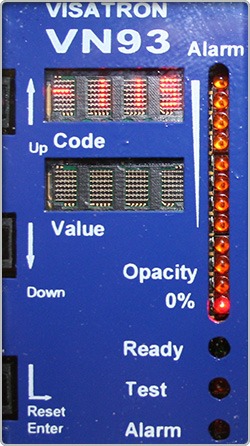

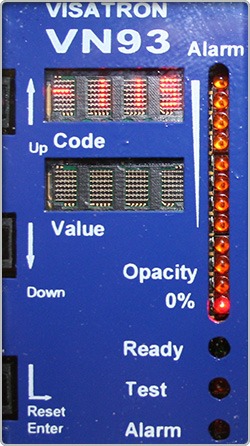

VN/93 Fault Indication

Fault indication on LED- display

Click on fault indication link to view maintenance procedure

CAUTION!

Fault location has to be done when the engine is stopped!

Click on fault indication link to view maintenance procedure

CAUTION!

Fault location has to be done when the engine is stopped!

Your professional partner within Oil Mist Detector technology. Engine Protection Partner AS is a Schaller Automation authorized repair, sales and service centre based in Scandinavia. Headquarter for Norway, Svalbard, Jan Mayen, Faroe Islands, Aaland Islands, Sweden, Finland, Denmark, Iceland, Estonia, Latvia, Lithuania and Greenland. We are represented world-wide! Main training center for clients such engine manufactorers, the norwegian military, scandinavian maritime schools, hundreds of ship owners and more.

© The information and media under this domain (www.epp.no) is the property of Engine Protection Partner AS (Reg. no.: 976 683 560) and may not be copied or used for any purpose other than for which it is supplied without the express written consent of Engine Protection Partner AS. If any of the aforementioned elements are copied without our written consent, this will lead to legal action from our side! The information on this website is reserved against spelling/typing errors.