Products

Why use Visatron oil mist detector systems?

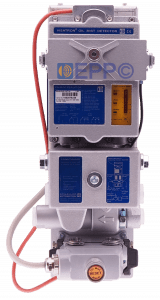

Oil Mist Detectors protect large Diesel, Gas and Dual Fuel engines of all application from heavy consequential damage due to oil mist explosions as a result of overheating of bearings or other moving parts. All Schaller VISATRON® Oil Mist Detection Systems continuously draw the atmosphere from every compartment of the engine’s crankcase by the use of a suction system. The suction vacuum required is generated by a wear-free air jet pump within the device, fed by compressed air.

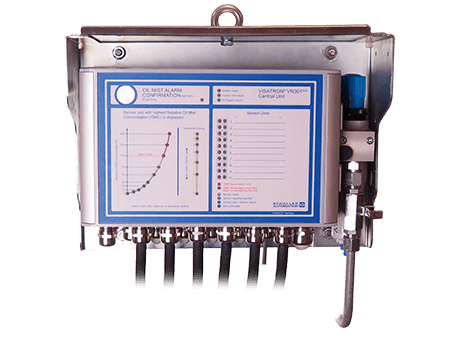

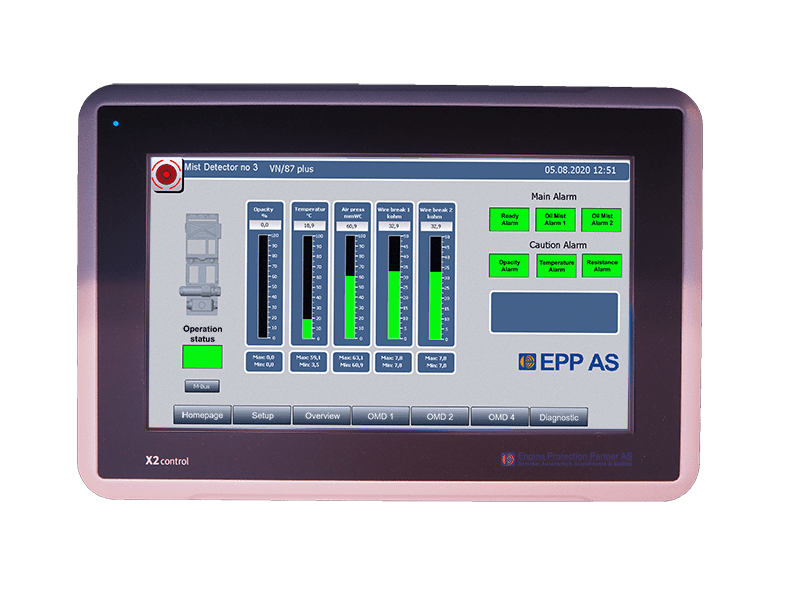

The VN301plus system consist of a central unit which up to 20 sensors (master slave version) can be connected. Each sensor monitors one crankcase compartment independently and is an standalone unit. When a sensor is replaced, the surrounding sensors ensure that the crankcase is monitors under safe conditions.

The new VN2020 Oil Mist Detector will be available during 2020! The VN2020 replaces the VN115/87plus and VN116/87plus. The VN2020 will be especially for 4- stroke engine marked. The VN301plus replaces VN215/87plus for the 2- stoke marked!

Continuously and simultaneously evacuate crankcase atmosphere from each crankcase compartment between two main bearings. The VN 115 and VN 116 series use a header-suction-tube system for this purpose.

The VN/87 EMC generation consist of: VN 115/87 EMC, VN 116/87 EMC & VN 215/87 EMC. The VN/87 EMC is the successor of the VN/79 & VN/82 generations. The VN/87 was placed into the market in 1985 and was in production until the system was replaced by the VN/87 EMC in 1998. The VN/87 EMC was then replaced by the VN/87plus in 2008.

The VN/93 generation did not replace any of our other oil mist detector generations but was a supplement to the other systems. The VN/93 generation was launched into the market in 1997 and production line stopped in 2019. It is easy to identify the VN/93 generation as this is the only oil mist detector by Schaller Automation that was not in a grey, metallic colour, but white.

This innovative 3-axis acceleration monitoring system is specially designed to monitor the vibration limits set by DIN ISO 10816-6 on combustion engines larger than 100 kW.

The ‘BEARing MOnitoring System’ for oil lubricated slide bearings detects highly sensitive bearing damage even before it starts, even before signs of overheating.

- Visatron pressure reducer

- Sampling funnels

- Oil separators

- Installation kit / pipe system

- Digital U-tube manometer

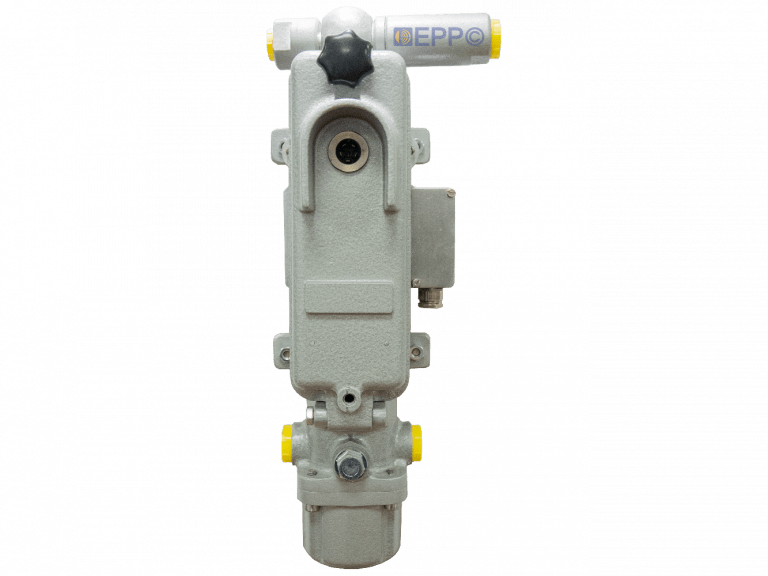

- Syphon block vn180, vn115 and vn116

- Driving air conditioning kit

- Remote indicator II

Over the years Schaller Automation has created and supplied the world with a range of different generations of models. Below you will the historical models Schaller Automation has produced. These are the models that had a great impact on Schaller Automations standing in the industry.