The Visatron VN/87 Generation

The Schaller Automation Visatron VN/87plus generation consist of: VN 115/87plus, VN 116/87plus & VN 215/87plus. The VN87plus is the successor of the VN/87 EMC. The VN/87plus was placed into the market in 2008. It was in production until the system was replaced by VN2020 and VN301plus in 2020. The VN/87plus was mainly used for 4-stroke engine market, and the system requires a single tube installation. The VN 116/87plus and VN 215/87plus was mainly used for the 2-stroke engine market. The VN 215/87plus indicates during a high oil mist concentration alarm which compartment the oil mist is coming from. The VN 116/87plus indicates from what side, the oil mist concentration is coming from. The VN 115/87plus is during a high oil mist concentration alarm, indicates that there is oil mist concentration in engine. The VN 115/87plus does this without any compartment location of the oil mist.

VN 115/87plus

The VN 115 and VN 116 series use a header-suction-tube system for this purpose. The oil mist detector is positioned in the middle between two header-suction-tube sections located on the engine sides. From these sections, single-suction tubes branch off near the compartments. These tubes are considerably thinner than the header-suction-tubes and they have a throttling effect. Owing to the large header-suction-tube diameter the vacuum and consequently the sample flow at each suction point remain virtually constant. The arrangement of the detector in the middle of the header-suction tube results in an optimally short sample running time in the tube system.

VN 116/87plus

It compares oil mist concentration from each side of the header-suction-tube section and responds if there is a difference. This being a sure sign for an overheating damage in the compartment group with the higher opacity. The differential alarm level is carried along with regard to its sensitivity relating to the 10-stage adjustment of the alarm level which is also available for VN 115. For measuring the opacity differential, the sample flows of both header-suction-tube sections are fed to the turbid metric channel one after the other by closing the respective tube sections alternately by means of reed valves.

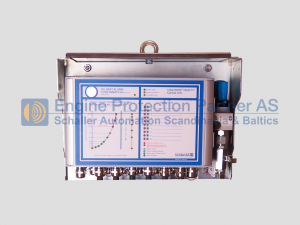

VN 215/87plus

VISATRON VN215/87plus, operates in the same way as the VN 116/87plus as far as the tripping of an alarm is concerned. However, it is able to additionally indicate the suction point with the highest opacity and thus the compartment in which the overheating damage has occurred. Unlike the other types, the VN 215 series has a single-suction-tube system, each compartment being connected by a separate tube to valve box designed for 10 suction lines. All procedures are similar to those of type VN 116 series. Normally, the compound opacity of the oil mist from all compartments will continuously be measured. If the opacity exceeds the damage check starting threshold a damage check will be executed. lf the differential alarm level is exceeded, an alarm causing the automatic stop of the machine or a speed reduction will immediately be tripped.